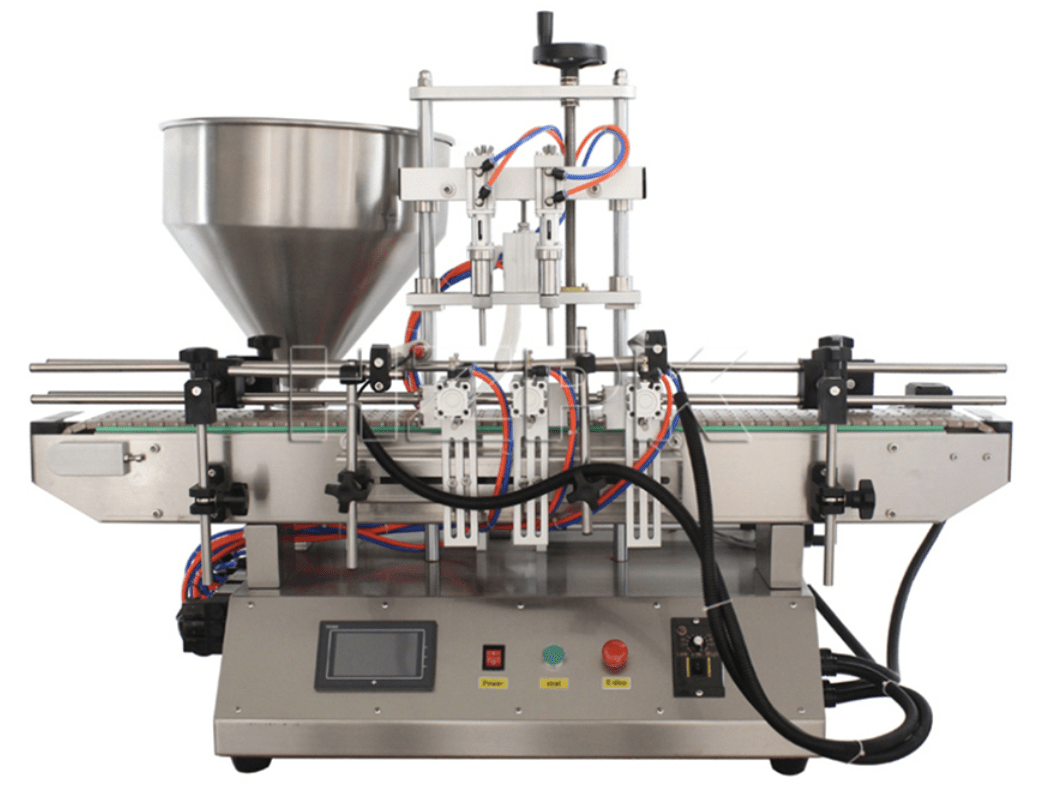

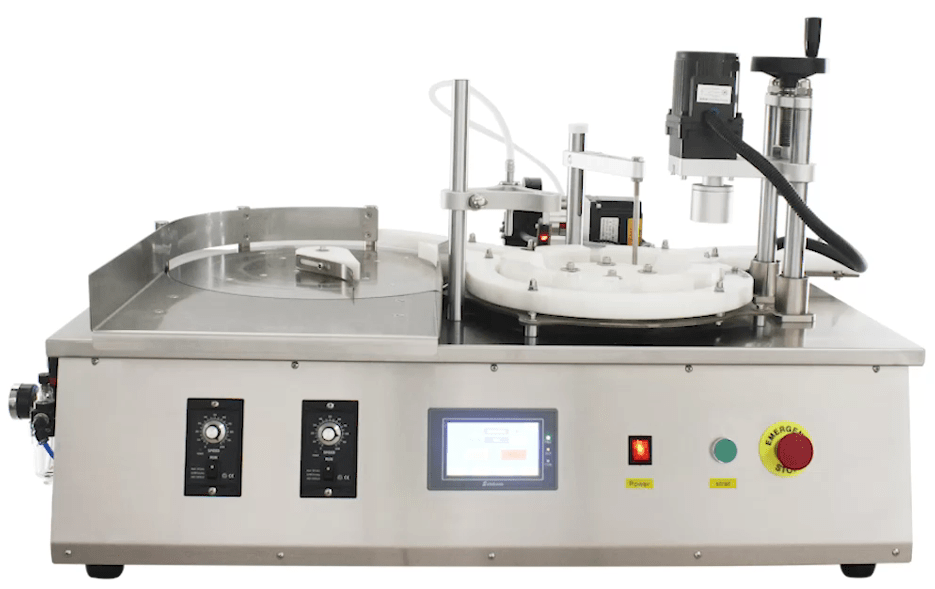

Automatic Bottle Liquid Filling Capping Machine

The tabletop liquid filling and capping machine is a compact and efficient solution designed for filling and capping liquid products in small volumes, typically ranging from 5 to 50 ml. It is widely used in industries such as pharmaceuticals, cosmetics, food and beverage, and chemicals.

Description

Features:

- Interface Operation System: The user-friendly interface allows operators to easily control and monitor the machine’s functions, typically using touchscreen controls or intuitive buttons.

- PLC Control: The PLC (Programmable Logic Controller) ensures precise and reliable control over the filling and capping processes, with customizable parameters and smooth integration with other equipment.

- Bottle Detection System: The machine features sensors or detectors to confirm the presence of bottles. If no bottle is detected in position, the filling or capping process will not begin, ensuring operational safety and minimizing product waste.

- Suitability for 5-50 ml Vials: Specifically designed for filling vials between 5 and 50 ml, making it ideal for industries like pharmaceuticals, cosmetics, and specialty chemicals.

- Stable Structure: The machine’s robust structure minimizes vibrations, ensuring steady operation and consistent performance, even during high-speed production cycles.

- Peristaltic Pump Filling: Using a peristaltic pump guarantees accuracy, cleanliness, and versatility, preventing contamination and spillage during liquid dispensing.

- Emergency Stop Function: The emergency stop button allows the machine to be quickly halted in critical situations, ensuring operator safety and preventing potential damage to the equipment.

Specifications:

- Voltage: 220V, 50-60Hz

- Filling Volume: 5-100 ml

- Filling Accuracy: ±0.5-1 ml

- Bottle Diameter: 20-50 mm

- Cap Diameter: 15-25 mm / 25-35 mm / 35-45 mm

- Bottle Height: 40-100 mm

- Air Compressor Required: Yes, for liquid products only

- Cap Feeding: Manual