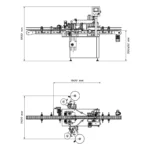

Double Sided Round Surface Labeling Machine

Double Sided Round Surface Labeling Machine

a state-of-the-art industrial solution designed for efficient and precise labeling of products with both double-sided and round surfaces. This automated machine ensures versatility in labeling applications, offering businesses a streamlined and high-speed solution for consistent and accurate labeling. Ideal for various product shapes and sizes, this labeling machine is a valuable asset for those seeking to enhance their production processes.

System: Linear

Working principle: Non-stop working

Construction: Chassis is painted aluminum, other surfaces are anodized aluminum.

Control unit: Omron or Beckhoff

Packaging: Plastic, glass, metal

Packing Diameter: 20-130mm

Module speed: 30m/min Servo motor driven

Label type: Self-adhesive (sticker)

Label height: 20mm-150mm / 20mm-230mm (only option available on machine)

Roll inner diameter: 74mm

Roll outer diameter: 300mm

Electricity requirement: 220V, 50Hz, single-phase

Air requirement: 6-8 Bar

Energy consumption: 3 kW

Air consumption: 300 lt/min (if necessary)

Weight: ~350 kg

Capacity: It varies according to the package diameter and label length.